Vistas:0 Autor:Christine Troutman – Director of Scientific Operations Hora de publicación: 2025-12-12 Origen:Sitio

Environmental monitoring might sound simple: collect air samples, record data, and move on. But anyone who has spent time in a cleanroom knows it is anything but. Between gowning, disinfecting, carrying equipment, labeling plates, and logging results, a “quick”sampling round can easily consume most of a shift.

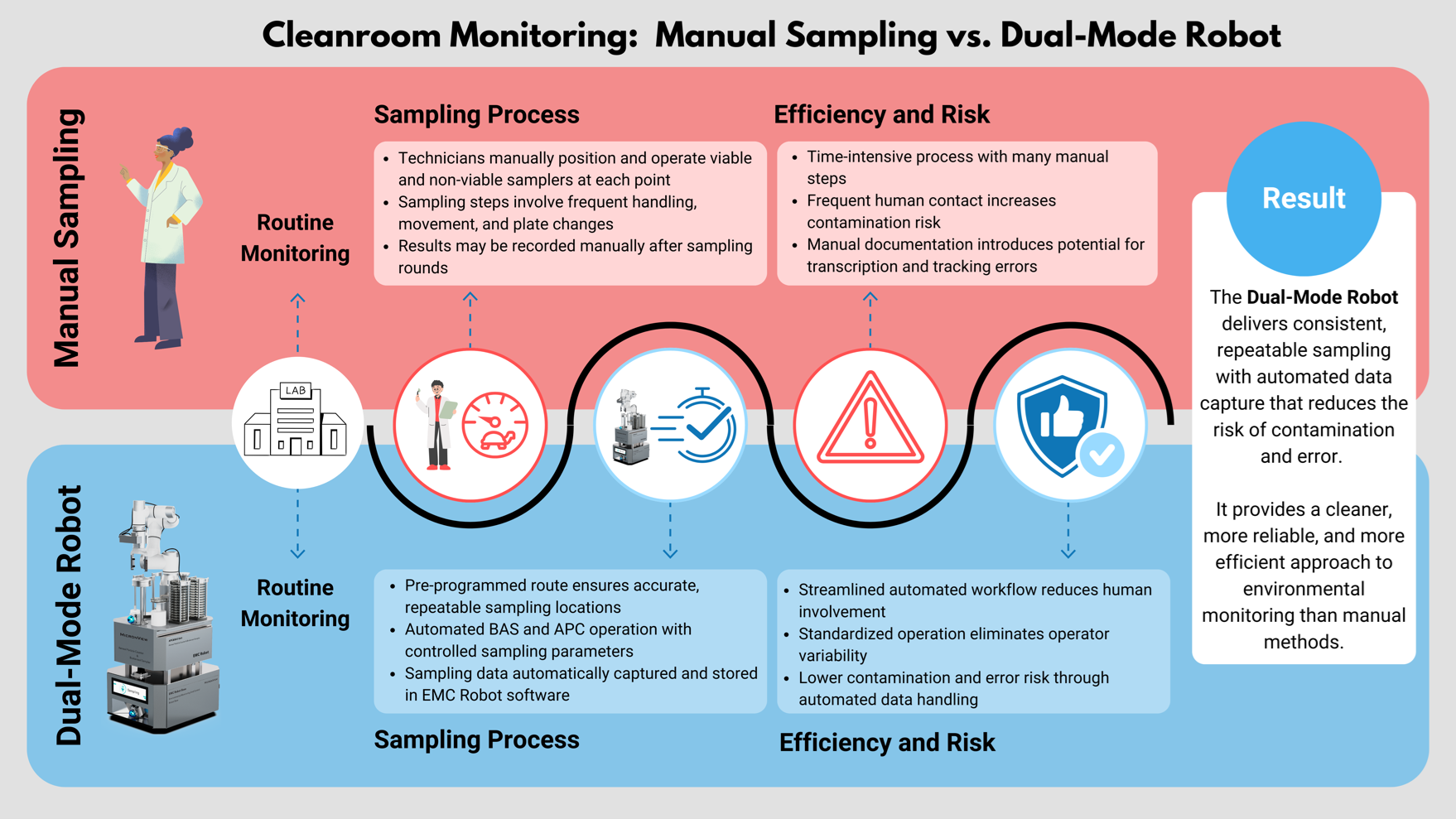

To demonstrate what that really looks like, this example compares traditional manual cleanroom monitoring performed by technicians with automated monitoring completed by MicronView’s Dual-Mode Robot, equipped with both a BioAerosol Sampler (BAS) and an Airborne Particle Counter (APC).

| EXAMPLE SCENARIO OVERVIEW |

Consider a 150 m² Grade C cleanroom, typical for a background or support area in sterile production. The environmental monitoring plan includes:

- 20 viable sampling points, using a 100 L/min active air sampler (500 L per point, 5 minutes each)

- 20 non-viable sampling points, using a 28.3 L/min portable particle counter (1 minute each)

That’s 40 total sampling locations, each requiring aseptic handling, precise documentation, and adherence to regulatory standards.

| MANUAL CLEANROOM MONITORING |

Preparation and Setup | Estimated time required: 45 minutes

Before sampling begins, technicians must gown up, disinfect the sampling equipment, label agar plates, and prepare logbooks or data entry system. Even small inefficiencies during this step, such as waiting for area clearance or retrieving materials, can delay sampling before it even starts.

Viable Sampling Workflow | Estimated time required: 2 hours 45 minutes

At each of the 20 viable locations, the operator positions the air sampler, verifies flow rate, and collects a 5-minute (500 L) sample. After each run, the plate is changed, sealed, labeled, and documented. Surfaces are disinfected between locations to minimize cross-contamination.

On paper, this sounds straightforward, but moving between points, double-checking labels, and handling plates under aseptic conditions adds up quickly. Occasional resamples for labeling errors or disturbances add even more time.

Non-Viable Sampling Workflow | Estimated time required: 1 hour

The non-viable sampling process is similar, but faster per point. The particle counter collects 1-minute samples at 28.3 L/min. However, operators must carefully position the probe to avoid interference, wipe surfaces before and after, and record or verify results manually.

Post-Sampling Handling and Documentation | 1 hour

When all sampling is complete, equipment must be disinfected again, plates sealed and transferred to incubation, and all data transcribed or verified to/from electronic systems. Data verification and report formatting extend this process further.

Total Manual Monitoring Time

| Step | Approximate Time |

| Preparation and gowning | 45 min |

| Viable sampling | 165 min |

| Non-viable sampling | 60 min |

| Cleaning and documentation | 60 min |

| Total elapsed time | ≈ 5 hours 30 min |

| Total labor | ≈ 6 person-hours |

Even with trained technicians working efficiently, manual cleanroom monitoring for a single large Grade C room typically consumes most of a workday.

| AUTOMATED CLEANROON MONITORING WITH THE DUAL-MODE ROBOT |

Now, imagine the same 40 sampling points monitored automatically by MicronView’s Dual-Mode Robot, a fully robotic platform that integrates a BioAerosol Sample (BAS) and an Airborne Particle Counter (APC). The system performs both viable and non-viable sampling sequentially, following a pre-set route across the cleanroom. This robotic platform is suitable for a wide range of cleanroom grades and applications, providing precise, efficient, and repeatable environmental monitoring.

System Configuration and Operation

The Dual-Mode Robot navigates using LiDAR and SLAM mapping, maintaining ±2 cm positioning accuracy. Sampling coordinates and heights are pre-designated within the EMC Robot software, allowing users to map and validate exact sampling points in advance. This reduces location error and ensures repeatable, validated sampling routes across every run.

At each designated point, the robotic BioAerosol Sampler (BAS) collects a 5-minute, 500 L air sample at 100 L/min. Using a six-axis robotic arm, the system automatically retrieves, places, and removes barcoded agar plates, logging each sample via barcode scanning to ensure complete traceability.

After the viable air sample is complete, the onboard Airborne Particle Counter (APC) performs a 1-minute total particle count at 28.3 L/min across multiple size channels. This sequential operation provides a comprehensive viable and non-viable particle profile for each location.

All sampling events are timestamped and mapped to their corresponding locations in the EMC Robot software. APC results are transmitted in real time, while viable sample data are automatically associated with their corresponding site and plate barcodes.

The software also allows users to program automated responses to over-threshold results, such as triggering immediate notifications, scheduling resampling, or flagging alerts for QA review. This functionality supports rapid investigation and aligns with Annex 1 expectations for proactive contamination control.

After completing all designated points, the robot automatically returns to its docking station to recharge. Reports, audit trail data, and complete sampling records are immediately available for QA review, with no manual transcription or data reconciliation required.

| COMPARATIVE EFFICIENCY ANALYSIS |

| Category | Human Operators | Dual-Mode Robot |

| Personnel required | 2-3 Technicians | 1 Robot SME |

| Preparation and gowning | 45 min | None |

| Viable sampling and movement | 165 min | 120 min |

| Non-viable sampling and movement | 60 min | Sequential ~ 20 min |

| Data logging and review | 60 min | 0 min |

| Error or resample risk | Moderate | Minimal |

| Total time | ≈ 5.5 hours | ≈ 2.5 hours unattended |

| Labor effort | ≈ 6 person-hours | < 0.5 person-hour |

In this simplified example, the Dual-Mode Robot reduces total monitoring time by roughly 55% and labor requirements by more than 90%, while eliminating sample location and manual transcription errors and ensuring synchronized, validated data.

| AUTOMATION AND THE NEXT ERA OF ENVIRONMENTAL MONITORING |

Reducing human presence in the cleanroom minimizes contamination risk, lowers the potential for sampling error, and frees technicians from repetitive tasks. The APC/BAS Dual-Mode Robot follows the same validated path every time, ensuring consistent, traceable data collection with every run. Results appear immediately in EMC Robot Software, allowing quality teams to review trends, investigate deviations, and respond in real time.

Manual environmental monitoring has long been the foundation of cleanroom quality assurance, but it is increasingly difficult to scale with modern manufacturing demands. Automation aligns with the intent of EU GMP Annex 1 by supporting continuous monitoring, improving data integrity, and enhancing contamination control strategies. The Dual-Mode Robot does not change what is measured, it transforms how efficiently it is done.

In this example, the impact is clear: 5.5 hours of manual work reduced to roughly 2 hours of unattended operation. Seven person-hours replaced by less than half. No gowning, no manual logging, and no variability. One robot can monitor multiple rooms in a single shift or operate overnight, providing continuous viable and non-viable monitoring without additional labor.

Cleanroom monitoring will always be essential. With MicronView’s Dual-Mode Robot, it is now consistent, scalable, and ready for the next generation of pharmaceutical manufacturing.